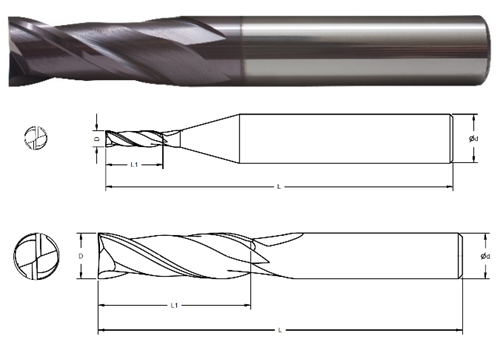

- Regular Length E/M (2FL)

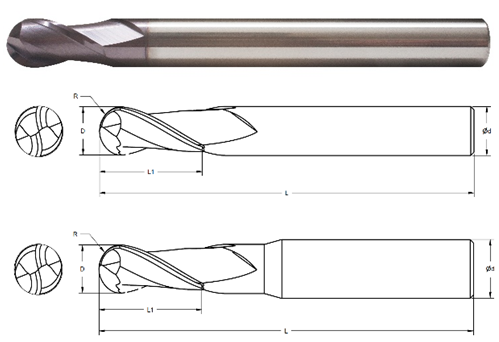

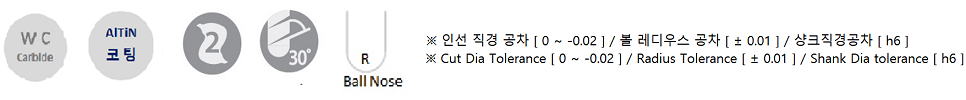

- Regular Length Ball E/M (2FL)

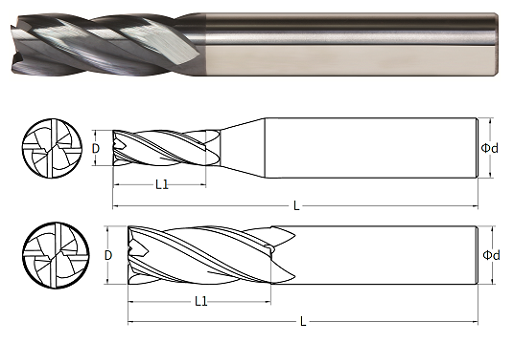

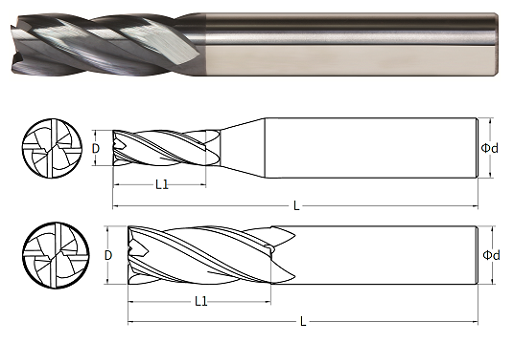

- Regular Length E/M (4FL)

- Power Regular Length E/M (2FL)

- Power Regular Length Ball E/M (2FL)

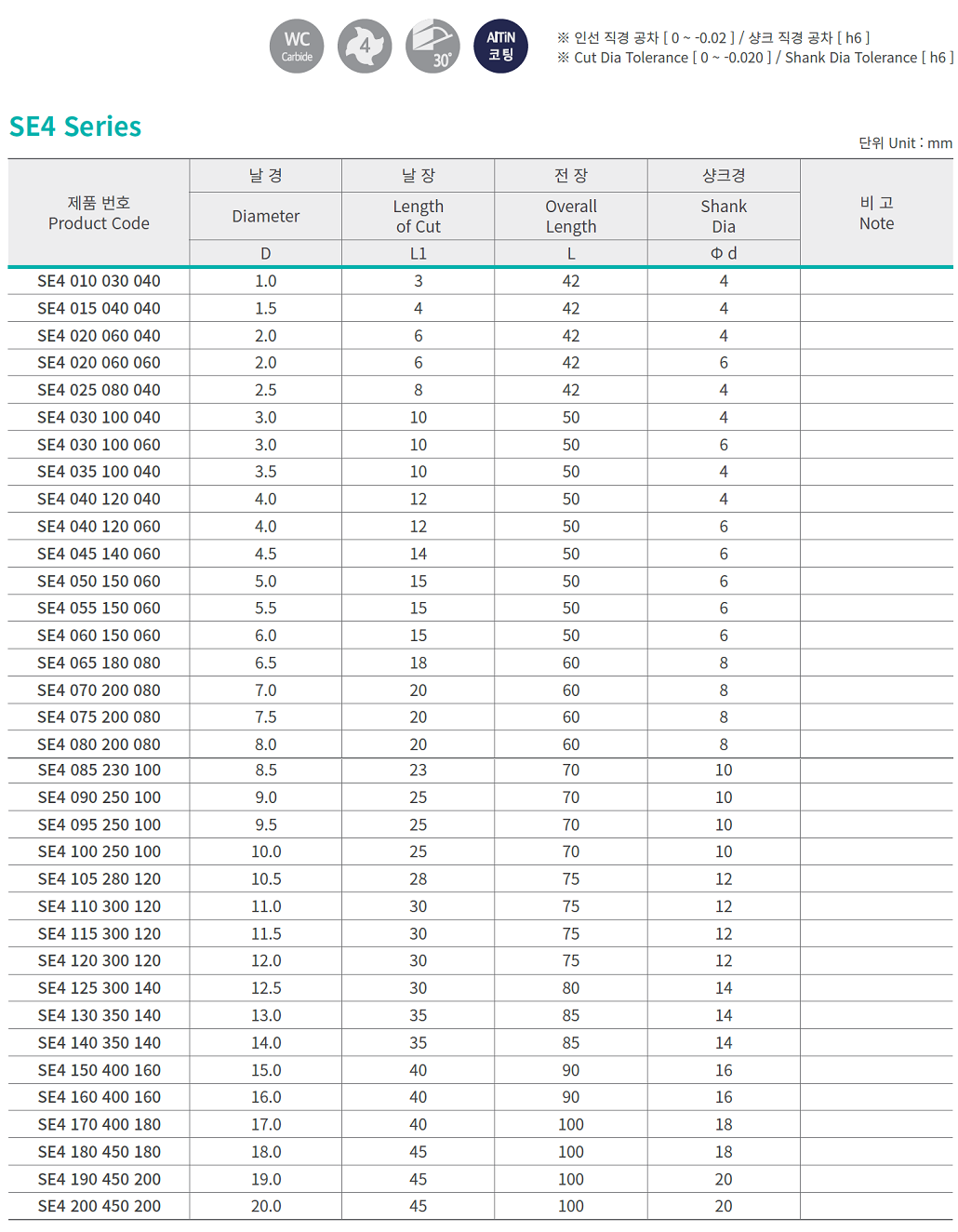

- Power Regular Length E/M (4FL)

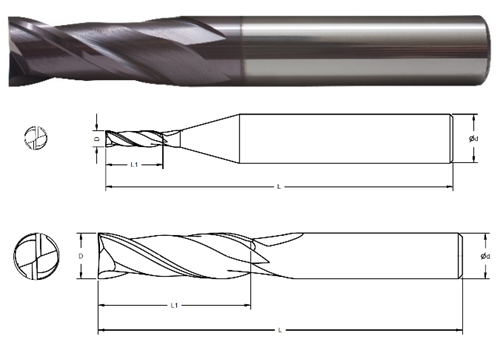

Regular Length E/M(2FL)

- Endmill for medium-hardness

- Pre-hardened steel, mold steel, alloy steels, carbon steels

- Excellent performance up to HRC 50

- Fast response and delivery to customers’ own dimensions and specifications

SE2 Series

| Product code |

Diameter |

Length of Cut |

Overall Length |

Shank Dia |

Note |

| D |

L1 |

L |

Φd |

| SE2 010 040 040 |

1.0 |

4 |

43 |

4 |

|

| SE2 010 040 060 |

6 |

|

| SE2 010 040 060 |

2.0 |

7 |

43 |

4 |

|

| SE2 020 070 060 |

6 |

|

| SE2 030 110 040 |

3.0 |

11 |

51 |

4 |

|

| SE2 030 110 060 |

6 |

|

| SE2 040 130 040 |

4.0 |

13 |

51 |

4 |

|

| SE2 040 130 060 |

6 |

|

| SE2 050 160 060 |

5.0 |

16 |

51 |

6 |

|

| SE2 060 160 060 |

6.0 |

16 |

51 |

6 |

|

| SE2 070 210 080 |

7.0 |

21 |

61 |

8 |

|

| SE2 080 210 080 |

8.0 |

21 |

61 |

8 |

|

| SE2 090 260 100 |

9.0 |

26 |

71 |

10 |

|

| SE2 100 260 100 |

10.0 |

26 |

71 |

10 |

|

| SE2 110 310 120 |

11.0 |

31 |

76 |

12 |

|

| SE2 120 310 120 |

12.0 |

31 |

76 |

12 |

|

| SE2 130 310 120 |

13.0 |

31 |

81 |

12 |

|

| SE2 140 360 140 |

14.0 |

36 |

86 |

14 |

|

| SE2 150 410 160 |

15.0 |

41 |

91 |

16 |

|

| SE2 160 410 160 |

16.0 |

41 |

91 |

16 |

|

| SE2 180 460 180 |

18.0 |

46 |

101 |

18 |

|

| SE2 190 460 200 |

19.0 |

46 |

101 |

20 |

|

| SE2 200 460 200 |

20.0 |

46 |

101 |

20 |

|

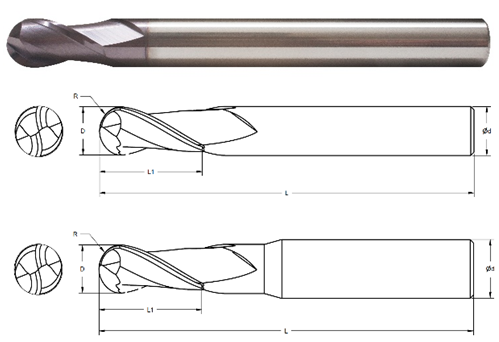

Regular Length Ball E/M (2FL)

- Ball-nose endmill for medium-hardness

- Pre-hardened steel, mold steel, alloy steels, carbon steels

- Excellent performance up to HRC 50

- Fast response and delivery to customers’ own dimensions and specifications

BE2 Series

| 제품번호 Product code |

Diameter |

Corner Radius |

Length of Cut |

Overall Length |

Shank Dia |

비고 Note |

| D |

R |

L1 |

L |

Φd |

| BE2 010 035 040 |

1.0 |

R 0.5 |

3.5 |

51 |

4 |

|

| BE2 010 035 060 |

6 |

|

| BE2 020 060 040 |

2.0 |

R 1.0 |

6 |

61 |

4 |

|

| BE2 020 060 060 |

6 |

|

| BE2 030 090 040 |

3.0 |

R 1.5 |

9 |

61 |

4 |

|

| BE2 030 090 060 |

6 |

|

| BE2 040 090 040 |

4.0 |

R 2.0 |

9 |

71 |

4 |

|

| BE2 040 090 060 |

6 |

|

| BE2 050 110 060 |

5.0 |

R 2.5 |

11 |

81 |

6 |

|

| BE2 060 130 060 |

6.0 |

R 3.0 |

13 |

91 |

6 |

|

| BE2 070 150 080 |

7.0 |

R 3.5 |

15 |

91 |

8 |

|

| BE2 080 150 080 |

8.0 |

R 4.0 |

15 |

101 |

8 |

|

| BE2 090 190 100 |

9.0 |

R 4.5 |

19 |

101 |

10 |

|

| BE2 100 200 100 |

10.0 |

R 5.0 |

19 |

101 |

10 |

|

| BE2 110 210 100 |

11.0 |

R 5.5 |

21 |

101 |

10 |

|

| BE2 120 230 120 |

12.0 |

R 6.0 |

23 |

111 |

12 |

|

| BE2 130 250 120 |

13.0 |

R 6.5 |

25 |

101 |

12 |

|

| BE2 140 270 120 |

14.0 |

R 7.0 |

27 |

101 |

12 |

|

| BE2 140 270 160 |

16 |

|

| BE2 160 310 160 |

16.0 |

R 8.0 |

31 |

151 |

16 |

|

| BE2 180 350 160 |

18.0 |

R 9.0 |

35 |

151 |

16 |

|

| BE2 180 350 180 |

18.0 |

R 9.0 |

35 |

151 |

18 |

|

| BE2 200 390 200 |

20.0 |

R 10.0 |

39 |

151 |

20 |

|

| BE2 250 510 250 |

25.0 |

R 12.5 |

51 |

181 |

25 |

|

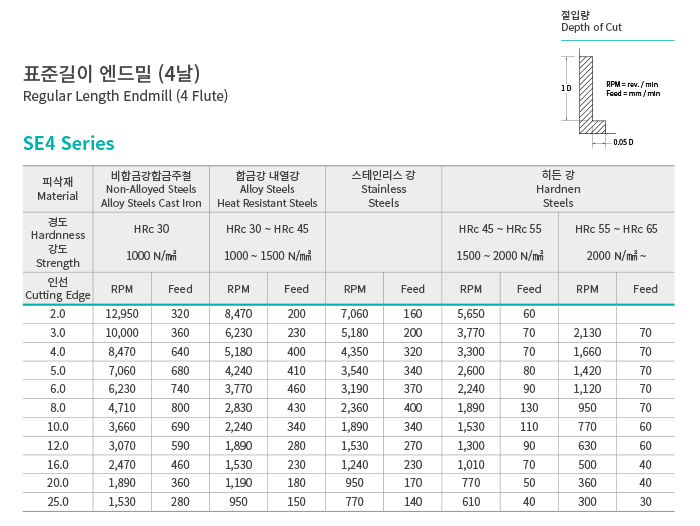

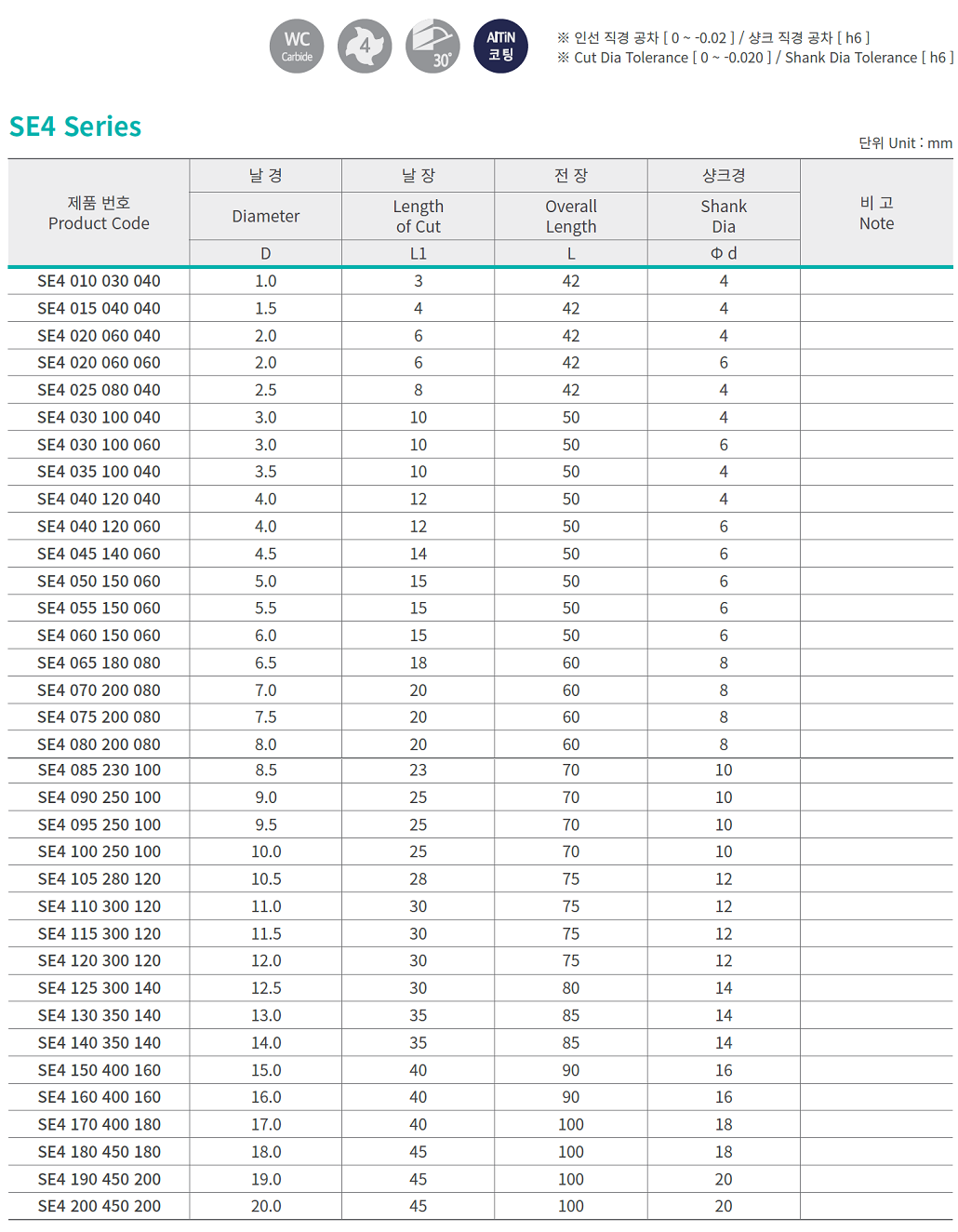

Regular Length E/M (4FL)

- Endmill for medium-hardness

- Suitable up to heat-treated HRC 55

- Suitable for tool steel, alloy steel, mold steel

- Fast response and delivery to customers’ own dimensions and specifications

Power Regular Length E/M (2FL)

- Endmill for medium-hardness

- Pre-hardened steel, mold steel, alloy steels, carbon steels

- Excellent performance up to HRC 50

- Fast response and delivery to customers’ own dimensions and specifications

XPE2 Series

| Product code |

Diameter |

Length of Cut |

Overall Length |

Shank Dia |

Note |

| D |

L1 |

L |

Φd |

| XPE2 010 035 060 |

1 |

3.5 |

51 |

6 |

|

| XPE2 020 070 060 |

2 |

7 |

51 |

6 |

|

| XPE2 030 090 060 |

3 |

9 |

56 |

6 |

|

| XPE2 040 110 060 |

4 |

11 |

56 |

6 |

|

| XPE2 050 140 060 |

5 |

14 |

56 |

6 |

|

| XPE2 060 160 060 |

6 |

16 |

61 |

6 |

|

| XPE2 070 190 080 |

7 |

19 |

66 |

8 |

|

| XPE2 080 210 080 |

8 |

21 |

71 |

8 |

|

| XPE2 090 240 100 |

9 |

24 |

71 |

10 |

|

| XPE2 100 260 100 |

10 |

26 |

76 |

10 |

|

| XPE2 110 290 120 |

11 |

29 |

76 |

12 |

|

| XPE2 120 310 120 |

12 |

31 |

81 |

12 |

|

| XPE2 130 360 120 |

13 |

36 |

91 |

12 |

|

| XPE2 140 360 160 |

14 |

36 |

91 |

16 |

|

| XPE2 150 390 160 |

15 |

39 |

91 |

16 |

|

| XPE2 160 410 160 |

16 |

41 |

101 |

16 |

|

| XPE2 170 440 160 |

17 |

44 |

101 |

16 |

|

| XPE2 180 460 160 |

18 |

46 |

101 |

16 |

|

| XPE2 190 490 200 |

19 |

49 |

101 |

20 |

|

| XPE2 200 460 200 |

20 |

46 |

101 |

20 |

|

| XPE2 210 460 200 |

21 |

46 |

101 |

20 |

|

| XPE2 220 460 200 |

22 |

46 |

101 |

20 |

|

| XPE2 230 510 250 |

23 |

51 |

121 |

25 |

|

| XPE2 240 510 250 |

24 |

51 |

121 |

25 |

|

| XPE 250 510 250 |

25 |

51 |

121 |

25 |

|

Power Regular Length Ball E/M (2FL)

- Ball-nose endmill for medium-hardness

- Pre-hardened steel, mold steel, alloy steels, carbon steels

- Excellent performance up to HRC 50

- Fast response and delivery to customers’ own dimensions and specifications

XPB2 Series

| Product code |

Diameter |

Corner Radius |

Length of Cut |

Overall Length |

Shank Dia |

비고 Note |

| D |

R |

L1 |

L |

Φd |

| XPB2 010 035 060 |

1 |

R 0.5 |

3.5 |

51 |

6 |

|

| XPB2 020 060 060 |

2 |

R 1.0 |

6 |

51 |

6 |

|

| XPB2 030 090 060 |

3 |

R 1.5 |

9 |

61 |

6 |

|

| XPB2 040 090 060 |

4 |

R 2.0 |

9 |

71 |

6 |

|

| XPB2 050 110 060 |

5 |

R 2.5 |

11 |

81 |

6 |

|

| XPB2 060 130 060 |

6 |

R 3.0 |

13 |

91 |

6 |

|

| XPB2 070 150 080 |

7 |

R 3.5 |

15 |

90 |

8 |

|

| XPB2 080 150 080 |

8 |

R 4.0 |

15 |

101 |

8 |

|

| XPB2 090 190 100 |

9 |

R 4.5 |

19 |

101 |

10 |

|

| XPB2 100 190 100 |

10 |

R 5.0 |

19 |

101 |

10 |

|

| XPB2 110 210 100 |

11 |

R 5.5 |

21 |

101 |

10 |

|

| XPB2 120 230 120 |

12 |

R 6.0 |

23 |

111 |

12 |

|

| XPB2 130 250 120 |

13 |

R 6.5 |

25 |

101 |

12 |

|

| XPB2 140 270 120 |

14 |

R 7.0 |

27 |

101 |

12 |

|

| XPB2 160 310 160 |

16 |

R 8.0 |

31 |

151 |

16 |

|

| XPB2 180 350 160 |

18 |

R 9.0 |

35 |

151 |

16 |

|

| XPB2 200 390 200 |

20 |

R 10.0 |

39 |

151 |

20 |

|

| XPB2 250 510 250 |

25 |

R 12.5 |

51 |

181 |

25 |

|

Power Regular Length E/M (4FL)

- Endmill for medium-hardness

- Suitable up to heat-treated HRC 50

- Suitable for tool steel, alloy steel, mold steel

- Fast response and delivery to customers’ own dimensions and specifications

XPE4 Series

| Product code |

Diameter |

Length of Cut |

Overall Length |

Shank Dia |

Note |

| D |

L1 |

L |

Φd |

| XPE4 010 035 060 |

1 |

3.5 |

51 |

6 |

|

| XPE4 020 070 060 |

2 |

7 |

51 |

6 |

|

| XPE4 030 090 060 |

3 |

9 |

56 |

6 |

|

| XPE4 040 110 060 |

4 |

11 |

56 |

6 |

|

| XPE4 050 140 060 |

5 |

14 |

56 |

6 |

|

| XPE4 060 160 060 |

6 |

16 |

61 |

6 |

|

| XPE4 070 190 080 |

7 |

19 |

66 |

8 |

|

| XPE4 080 210 080 |

8 |

21 |

71 |

8 |

|

| XPE4 090 240 100 |

9 |

24 |

71 |

10 |

|

| XPE4 100 260 100 |

10 |

26 |

76 |

10 |

|

| XPE4 110 290 120 |

11 |

29 |

76 |

12 |

|

| XPE4 120 310 120 |

12 |

31 |

81 |

12 |

|

| XPE4 130 360 120 |

13 |

36 |

91 |

12 |

|

| XPE4 140 360 160 |

14 |

36 |

91 |

16 |

|

| XPE4 150 390 160 |

15 |

39 |

91 |

16 |

|

| XPE4 160 410 160 |

16 |

41 |

101 |

16 |

|

| XPE4 170 440 160 |

17 |

44 |

101 |

16 |

|

| XPE4 180 460 160 |

18 |

46 |

101 |

16 |

|

| XPE4 190 490 200 |

19 |

49 |

101 |

20 |

|

| XPE4 200 460 200 |

20 |

46 |

101 |

20 |

|

| XPE4 210 460 200 |

21 |

46 |

101 |

20 |

|

| XPE4 220 460 200 |

22 |

46 |

101 |

20 |

|

| XPE4 230 510 250 |

23 |

51 |

121 |

25 |

|

| XPE4 240 510 250 |

24 |

51 |

121 |

25 |

|

| XPE 250 510 250 |

25 |

51 |

121 |

25 |

|

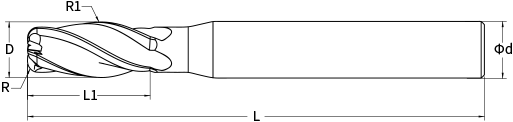

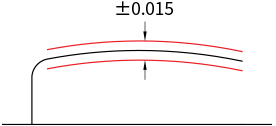

Turbine Mill

Barrel-Shape

- Exceptional performance on 5-axis CNC for semi-finishing and finishing.

- Achieves both tooling time reduction and precision.

- Data available for customers’ CNC programming.

- Specially designed for improved quality and productivity in tooling of turbine blades, impellers, blade disks, and aerospace industry blades.

TBBL Series

제품번호

Product code |

날경 |

코너 반지름 |

인선 반지름 |

날장 |

전장 |

샹크경 |

날수 |

비고

Note |

| Diameter |

Coner

Radius |

Outdia

Radius |

Length

of Cut |

Overall

Length |

Shank

Dia |

Number

of Flutes |

| D |

R |

R1 |

L1 |

L |

Φd |

F |

| TBBL 120 025 120 |

12.0 |

2.5 |

60 |

25 |

90 |

12 |

4 |

|

제품번호

Product Code |

TBBL 120 025 120 |

날경

Diameter

D |

12.0 |

코너 반지름

Coner Radius

R |

2.5 |

인선 반지름

Outdia Radius

R1 |

60 |

날장

Length of Cut

L1 |

25 |

전장

Overall Length

L |

90 |

샹크경

Shank Dia

Φd |

12 |

날수

Number of Flutes

F |

4 |

비고

Note |

|